Ultimate Guide To Factorio Space Age Pipe Throughput

What is the significance of factoriopace age pipe throughput? Factoriopace age pipe throughput measures the rate at which a pipe can transport fluid in a Factorio game. It is an important aspect of the game, as it can affect the efficiency of your factory and your ability to produce items.

The throughput of a pipe is determined by its diameter and the type of fluid that is being transported. Larger diameter pipes can transport more fluid than smaller diameter pipes, and certain types of fluids, such as oil, have a higher viscosity than others and therefore require more energy to pump.

There are a number of ways to increase the throughput of a pipe. One way is to increase the diameter of the pipe. Another way is to use a pump to increase the pressure of the fluid. Finally, you can also use a fluid wagon to transport fluid over long distances.

- Outlander Jamie Actor

- Toby Keiths Car Collection

- Jason Beghe

- Zach And Jeremy Roloff Feud

- Chris Norman And Suzi Quatro

Increasing the throughput of your pipes can help you to improve the efficiency of your factory and increase your production output. By understanding the factors that affect pipe throughput, you can make informed decisions about how to design your factory and which pipes to use.

Factoriopace Age Pipe Throughput

There are a number of key aspects that affect factoriopace age pipe throughput, including:

- Pipe diameter

- Fluid viscosity

- Pump pressure

- Pipe length

Pipe Diameter

The diameter of a pipe is the most important factor affecting its throughput. Larger diameter pipes can transport more fluid than smaller diameter pipes. This is because larger diameter pipes have a larger cross-sectional area, which allows more fluid to flow through them.

Fluid Viscosity

The viscosity of a fluid is a measure of its resistance to flow. Fluids with a higher viscosity are more difficult to pump than fluids with a lower viscosity. This is because fluids with a higher viscosity have a greater tendency to stick to the sides of the pipe, which reduces the amount of fluid that can flow through the pipe.

Pump Pressure

Pump pressure is the amount of force that is applied to a fluid to move it through a pipe. Increasing the pump pressure can increase the throughput of a pipe. This is because increased pump pressure overcomes the resistance of the fluid to flow, allowing more fluid to flow through the pipe.

Pipe Length

The length of a pipe also affects its throughput. Longer pipes have a greater resistance to flow than shorter pipes. This is because the fluid has to travel a longer distance through the pipe, which gives it more time to stick to the sides of the pipe and reduce the amount of fluid that can flow through the pipe.

Factoriopace Age Pipe Throughput

Factoriopace age pipe throughput plays a crucial role in determining the efficiency of fluid transportation in a Factorio game. Understanding the various aspects that influence pipe throughput can help players optimize their factory designs and production output.

- Pipe Diameter: Larger diameter pipes allow for higher fluid flow rates.

- Fluid Viscosity: Fluids with lower viscosity flow more easily through pipes.

- Pump Pressure: Increasing pump pressure can overcome resistance and enhance throughput.

- Pipe Length: Longer pipes introduce greater resistance to fluid flow, reducing throughput.

- Pipe Material: Different pipe materials can affect throughput due to varying friction coefficients.

- Pipe Connections: Ensuring proper pipe connections minimizes leakage and maintains optimal throughput.

- Fluid Temperature: Temperature can influence fluid viscosity and thus impact throughput.

These aspects are interconnected and should be considered holistically when designing fluid transportation systems. For instance, using larger diameter pipes with lower viscosity fluids and high pump pressure can significantly increase throughput. Additionally, minimizing pipe length and optimizing pipe connections can further enhance efficiency. Understanding these factors allows players to tailor their pipe networks to meet the specific demands of their Factorio factories.

Pipe Diameter

In factoriopace age, pipe throughput is a crucial aspect of fluid transportation efficiency. Pipe diameter plays a significant role in determining the throughput capacity of a pipe. Larger diameter pipes facilitate higher fluid flow rates due to their increased cross-sectional area. This allows for a greater volume of fluid to pass through the pipe per unit time.

The relationship between pipe diameter and throughput can be understood through the principles of fluid dynamics. According to the Hagen-Poiseuille equation, the flow rate of a fluid through a pipe is directly proportional to the fourth power of the pipe's radius. This means that even a modest increase in pipe diameter can result in a substantial increase in throughput.

In practical applications within factoriopace age, optimizing pipe diameter is essential for ensuring efficient fluid transportation. For instance, in a scenario where high volumes of fluid need to be transported over long distances, utilizing larger diameter pipes can significantly reduce pressure drop and minimize energy consumption. Conversely, in situations where space is constrained or cost is a limiting factor, smaller diameter pipes can be employed, albeit with a compromise in throughput capacity.

Understanding the connection between pipe diameter and factoriopace age pipe throughput empowers players to make informed decisions when designing their fluid transportation networks. By carefully considering the required flow rates and optimizing pipe diameters, players can achieve efficient and cost-effective fluid transportation systems.

Fluid Viscosity

In the context of factoriopace age, fluid viscosity plays a significant role in determining pipe throughput. Viscosity is a measure of a fluid's resistance to flow. Fluids with lower viscosity flow more easily through pipes, resulting in higher throughput rates.

The relationship between fluid viscosity and pipe throughput can be understood through the principles of fluid dynamics. The Hagen-Poiseuille equation, which governs fluid flow in pipes, states that the flow rate is inversely proportional to the fluid's viscosity. This means that fluids with lower viscosity experience less resistance to flow and can achieve higher flow rates through pipes.

In practical applications within factoriopace age, understanding the impact of fluid viscosity on pipe throughput is essential for optimizing fluid transportation systems. For instance, in scenarios where high throughput rates are required, selecting fluids with lower viscosity can significantly improve the efficiency of the system. This is particularly important in large-scale fluid transportation networks, where even small reductions in viscosity can lead to substantial increases in throughput.

Furthermore, the viscosity of fluids can also affect the choice of pipes and pumps used in a factoriopace age system. Fluids with higher viscosity may require larger diameter pipes and more powerful pumps to achieve the desired throughput rates. Considering the viscosity of the fluids being transported is crucial for designing cost-effective and efficient fluid transportation systems.

In summary, understanding the connection between fluid viscosity and factoriopace age pipe throughput is essential for optimizing fluid transportation systems. By carefully considering the viscosity of the fluids being transported and selecting appropriate pipes and pumps, players can achieve efficient and cost-effective fluid transportation networks, maximizing the throughput rates and overall performance of their factoriopace age systems.

Pump Pressure

In the context of factoriopace age, pump pressure plays a crucial role in enhancing pipe throughput. By increasing the pressure of the fluid being pumped, the resistance to flow through the pipe can be overcome, resulting in higher throughput rates.

The relationship between pump pressure and pipe throughput can be understood through the principles of fluid dynamics. The Hagen-Poiseuille equation, which governs fluid flow in pipes, states that the flow rate is directly proportional to the pressure gradient applied to the fluid. This means that increasing the pump pressure increases the pressure gradient, leading to higher flow rates through the pipe.

In practical applications within factoriopace age, optimizing pump pressure is essential for achieving efficient fluid transportation. In scenarios where high throughput rates are required, increasing the pump pressure can significantly improve the flow of fluids through pipes. This is particularly important in large-scale fluid transportation networks, where even small increases in pump pressure can lead to substantial increases in throughput.

Furthermore, the pump pressure also affects the choice of pipes used in a factoriopace age system. Higher pump pressure may require thicker and more robust pipes to withstand the increased pressure. Considering the pump pressure and the compatibility of pipes is crucial for designing safe and efficient fluid transportation systems.

In summary, understanding the connection between pump pressure and factoriopace age pipe throughput is essential for optimizing fluid transportation systems. By carefully considering the required throughput rates and selecting appropriate pumps and pipes, players can achieve efficient and cost-effective fluid transportation networks, maximizing the throughput rates and overall performance of their factoriopace age systems.Pipe Length

In the context of factoriopace age, understanding the impact of pipe length on throughput is crucial for designing efficient fluid transportation systems. Longer pipes introduce greater resistance to fluid flow, resulting in reduced throughput rates.

The relationship between pipe length and throughput can be understood through the principles of fluid dynamics. The Hagen-Poiseuille equation, which governs fluid flow in pipes, states that the flow rate is inversely proportional to the length of the pipe. This means that as the length of the pipe increases, the resistance to flow increases, leading to a decrease in the flow rate.

In practical applications within factoriopace age, considering pipe length is essential for optimizing fluid transportation systems. In scenarios where high throughput rates are required, minimizing the length of pipes can significantly improve the efficiency of the system. This is particularly important in large-scale fluid transportation networks, where even small reductions in pipe length can lead to substantial increases in throughput.

Furthermore, the length of pipes also affects the choice of pumps used in a factoriopace age system. Longer pipes may require more powerful pumps to overcome the increased resistance to flow and achieve the desired throughput rates. Considering the length of pipes and the compatibility of pumps is crucial for designing cost-effective and efficient fluid transportation systems.

In summary, understanding the connection between pipe length and factoriopace age pipe throughput is essential for optimizing fluid transportation systems. By carefully considering the required throughput rates, minimizing the length of pipes, and selecting appropriate pumps, players can achieve efficient and cost-effective fluid transportation networks, maximizing the throughput rates and overall performance of their factoriopace age systems.

Pipe Material

In the context of factoriopace age, understanding the impact of pipe material on throughput is crucial for designing efficient fluid transportation systems. Different pipe materials exhibit varying friction coefficients, which can significantly affect the flow rate of fluids through the pipes.

- Facet 1: Friction Coefficient and Material Properties

The friction coefficient of a pipe material is a measure of the resistance to fluid flow caused by the interaction between the fluid and the pipe's inner surface. Materials with lower friction coefficients, such as stainless steel or plastic, allow for smoother fluid flow, resulting in higher throughput rates.

- Facet 2: Pipe Roughness and Throughput

The roughness of the pipe's inner surface also affects the friction coefficient. Rougher surfaces create more resistance to flow, leading to reduced throughput. For instance, galvanized steel pipes have a higher surface roughness compared to copper pipes, resulting in lower throughput rates for the same pipe diameter and fluid properties.

- Facet 3: Material Compatibility and Fluid Properties

The compatibility of the pipe material with the transported fluid is another important consideration. Certain fluids may react with specific pipe materials, causing corrosion or degradation over time. This can alter the friction coefficient and affect the throughput rate. For example, using copper pipes for transporting acidic fluids can lead to corrosion and reduced throughput.

- Facet 4: Economic Considerations and Material Selection

The cost and availability of different pipe materials also play a role in the selection process. While materials with lower friction coefficients, such as stainless steel, may offer higher throughput rates, they can be more expensive than other options. Factoriopace age players need to carefully consider the trade-offs between throughput, cost, and material properties when choosing the appropriate pipe material for their fluid transportation systems.

In summary, understanding the connection between pipe material and factoriopace age pipe throughput empowers players to make informed decisions when designing their fluid transportation networks. By considering the friction coefficients, surface roughness, fluid compatibility, and economic factors, players can optimize the throughput rates and overall performance of their factoriopace age systems.

Pipe Connections

In factoriopace age, ensuring proper pipe connections is crucial for maintaining optimal throughput and preventing costly leakages. Leakage can occur due to loose connections, damaged seals, or improper fittings, resulting in reduced fluid flow and compromised system efficiency.

Properly sealed and well-connected pipes minimize pressure loss and maintain the integrity of the fluid transportation system. This is particularly important in high-pressure or corrosive environments, where even minor leakages can pose significant safety and environmental hazards.

For instance, in a factoriopace age fluid transportation network carrying hazardous chemicals, ensuring proper pipe connections becomes paramount. Leakages can lead to the release of toxic substances, posing risks to human health and the environment. By implementing robust pipe connection practices, such as double-checking seals and using high-quality fittings, the risk of leakages can be significantly reduced, ensuring the safe and efficient operation of the system.

Furthermore, proper pipe connections contribute to the overall longevity and reliability of the fluid transportation system. Loose or poorly connected pipes can vibrate excessively, leading to wear and tear over time. By ensuring proper connections, the system's lifespan can be extended, reducing maintenance costs and unplanned downtime.

In summary, understanding the connection between pipe connections and factoriopace age pipe throughput highlights the importance of meticulous attention to detail during system design and installation. Proper pipe connections minimize leakage, maintain optimal throughput, enhance system safety, and contribute to the long-term reliability of the fluid transportation network.

Fluid Temperature

In factoriopace age, understanding the connection between fluid temperature and pipe throughput is essential for optimizing fluid transportation systems. Temperature can significantly influence the viscosity of fluids, which in turn affects the flow rate and overall throughput of the system.

- Facet 1: Viscosity and Temperature

Viscosity is a measure of a fluid's resistance to flow, and it is highly dependent on temperature. As temperature increases, the viscosity of most fluids decreases. This is because the higher thermal energy causes the fluid molecules to move more vigorously, reducing the intermolecular forces that cause resistance to flow.

- Facet 2: Temperature and Flow Rate

The Hagen-Poiseuille equation, which governs fluid flow in pipes, states that the flow rate is inversely proportional to the fluid's viscosity. Therefore, as temperature increases and viscosity decreases, the flow rate through the pipe increases, leading to higher throughput.

- Facet 3: Practical Implications in Factoriopace Age

In factoriopace age fluid transportation networks, managing fluid temperature can be crucial for achieving optimal throughput. For instance, in a system transporting heavy oil, increasing the temperature of the oil can significantly reduce its viscosity, allowing for higher flow rates and throughput. This can be achieved through the use of heat exchangers or by routing the pipes through warmer environments.

- Facet 4: Considerations and Limitations

While increasing temperature can improve throughput, it is essential to consider the limitations and potential drawbacks. Extremely high temperatures can damage pipes and seals, leading to leaks and reduced system efficiency. Additionally, certain fluids may undergo chemical reactions or degradation at elevated temperatures, making it necessary to carefully assess the compatibility of the fluid with the temperature range.

In summary, understanding the connection between fluid temperature and factoriopace age pipe throughput empowers players to design and operate efficient fluid transportation systems. By carefully considering the temperature-dependent viscosity of fluids and implementing appropriate temperature management strategies, players can optimize flow rates, maximize throughput, and ensure the smooth operation of their factoriopace age systems.

FAQs on Factoriopace Age Pipe Throughput

This section addresses frequently asked questions (FAQs) related to factoriopace age pipe throughput, providing clear and concise answers to common concerns or misconceptions.

Question 1: What factors primarily influence factoriopace age pipe throughput?

Answer: The primary factors affecting factoriopace age pipe throughput are pipe diameter, fluid viscosity, pump pressure, pipe length, and pipe material.

Question 2: How does increasing pipe diameter impact throughput?

Answer: Increasing pipe diameter significantly enhances throughput due to the larger cross-sectional area, which allows for a greater volume of fluid to flow through the pipe per unit time.

Summary of key takeaways or final thought: Understanding these factors and their impact on throughput is crucial for designing efficient fluid transportation systems in factoriopace age. By carefully considering each factor and optimizing the system accordingly, players can maximize throughput, reduce energy consumption, and ensure the smooth operation of their fluid networks.

Conclusion

In conclusion, factoriopace age pipe throughput is a critical aspect of fluid transportation system design and optimization. By understanding the interconnections between pipe diameter, fluid viscosity, pump pressure, pipe length, pipe material, fluid temperature, and pipe connections, players can make informed decisions to maximize throughput and minimize energy consumption.

Optimizing pipe throughput not only improves the efficiency of fluid transportation but also contributes to the overall performance and reliability of factoriopace age systems. By carefully considering the factors discussed in this article, players can design and implement efficient fluid networks that meet the demands of their industrial complexes, ensuring smooth operations and maximizing productivity.

- Home Alone Bird Lady

- Outlander Jamie Actor

- June 13 Zodiac

- Connor Mccaffey

- Mark Paul Gosselaar Mom And Dad

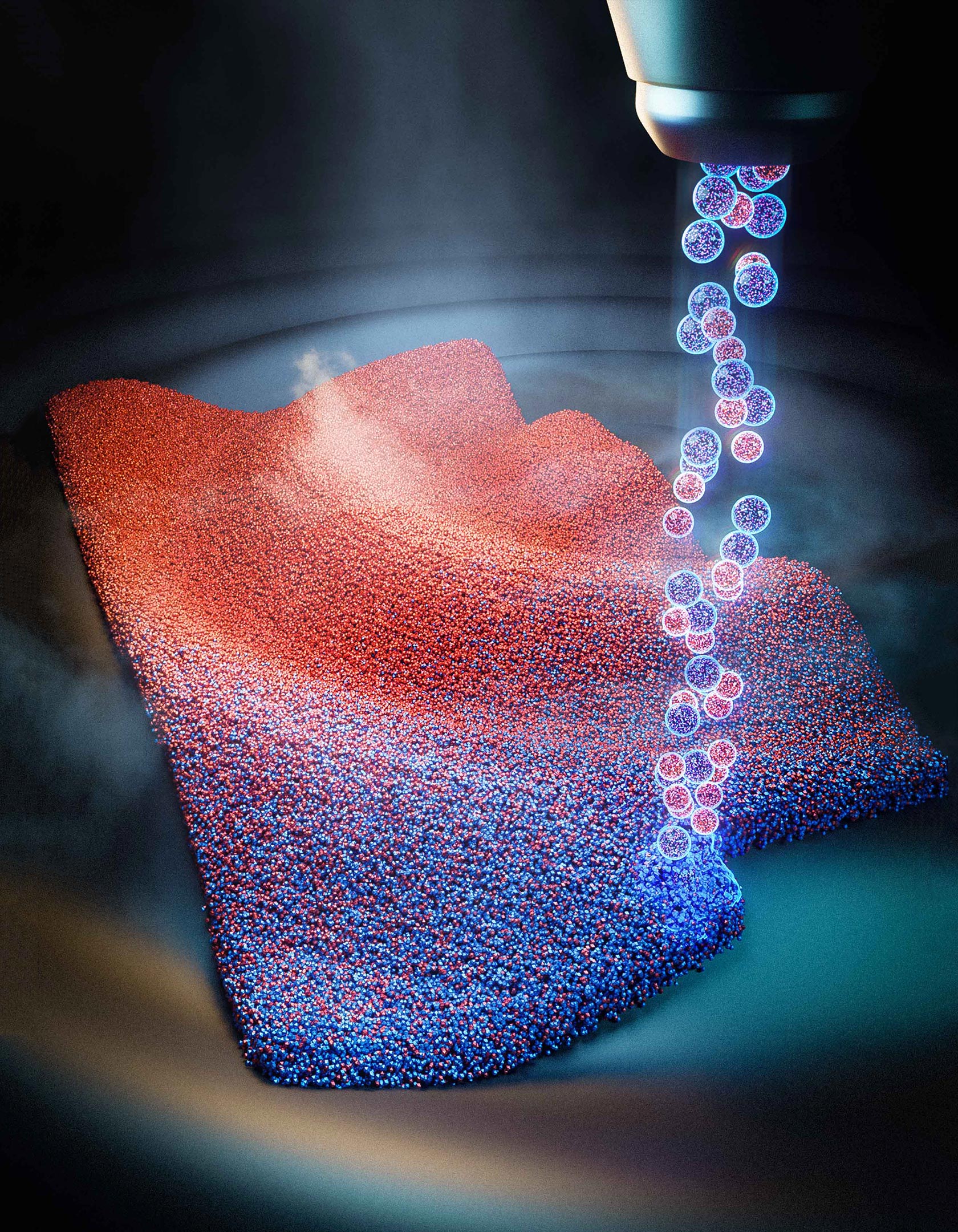

Revolutionary 3D Printing Technology a “Game Changer” for Discovering

Blog Exceeding Throughput Limits with Laser Communications

Baldur’s Gate, Hot Vampires, Moon Song, The Adventure Zone, Cat